Bayliss Boatyard’s Hull 5 Refit Project

When 64’ Old Reliable (Hull 5) was christened in 2005, she entered a fishing program that was built uniquely around fishing for marlin on the fly. Under new ownership, she returned to Bayliss Boatyard with a change in fishing-functionality in mind, presenting the team with a project that would prove to be their largest refit to date. Sixteen years of technological advances, management improvements, and an accelerated drive for excellence stood between the initial build and the beginnings of the refit project.

Boatyard Manager, Judd Beatty, oversaw the renovation of the newly named Mama Seata. “When Hull 5 came back and was for sale, it was in great condition. It just wasn’t up to date with what’s available now. Robb Crumpton chose to buy it and upgrade it to current standards. Now that it’s done, it is basically a new boat.”

Hull 5 Bayliss Boatyard arrival, August 2021

Bayliss Boatworks insists on delivering the highest quality boat and build-experience to each owner, and it’s with this same philosophy that every yard project is undertaken. The same resources, expertise, and manpower used in the company’s new construction builds, gets carried over into each of their yard projects. Broken down by department, we took a look at the work completed on Hull 5’s refit with each department depending on the other to produce a high-quality end result.

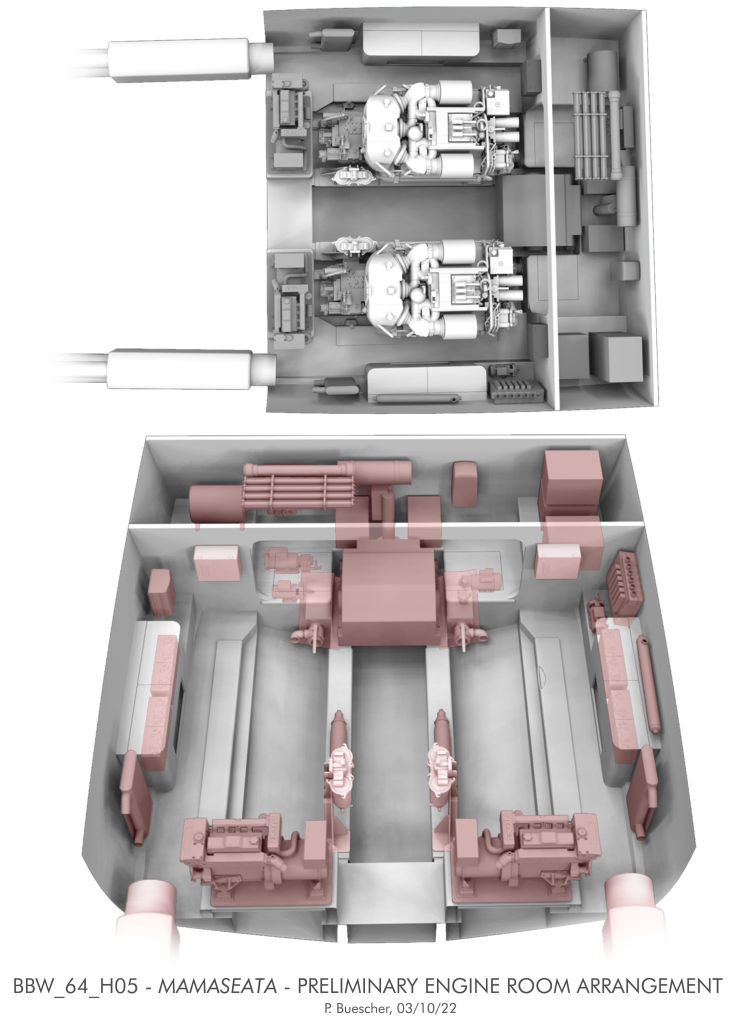

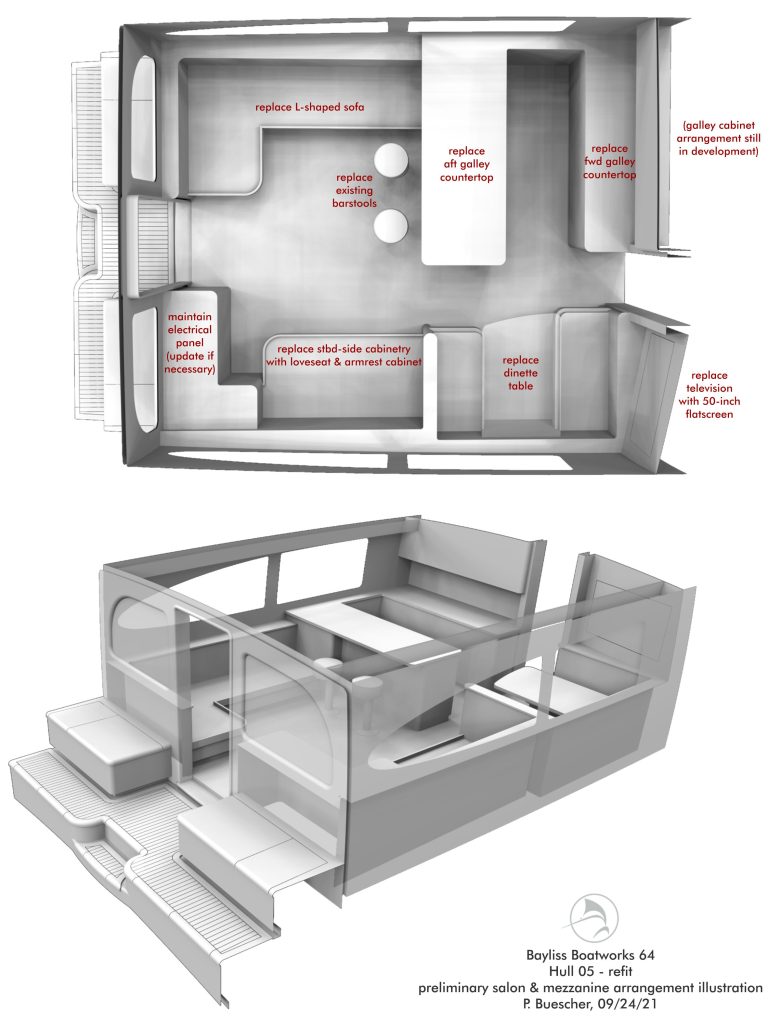

Design

The vision begins with design. Bayliss Boatwork’s design team worked together with the carpentry and mechanical departments to strategically plan and lay out the best models for their crews to follow, which started with a full scan of the boat. The engine room and pump room were redesigned to allow for equipment upgrades and additional power supply which included new engines, generators, and a gyro. Updated cabinetry items were designed to allow for custom nesting storage, and updated seating was added to the salon while a plan was created for renovations in the cockpit and flybridge.

Carpentry

With a new design in place, the exterior carpentry team was ready to get to work. The cockpit was completely modified with a new mezzanine layout, the addition of a transom fish box, and new teak decking, coverboards, and coaming. In the flybridge, console modifications were made to prepare for the addition of updated marine electronics items. Below deck, the engine room was renovated, including adjustments to the stringers and generator shelves to allow for the new power system.

While the exterior crew was busy updating the cockpit, bridge, and engine room, the cabinetry team began enhancing the timeless custom cabinetry items on Hull 5 by refinishing the interior teak veneer, as well as the wood countertops and galley floors to suit a more modern style. Custom nesting storage was fabricated and installed in the cabinets to best accommodate the new owners. The Metalworks department fabricated and installed a hinged bracket to the galley TV, which allowed for additional hidden storage. New bar stools and an L-shaped sofa and loveseat were added in the salon. In the lower accommodations, new teak shower doors were created and installed in all the heads, as well as a new teak ceiling in the companionway. Working closely with preferred vendors, the interior crews helped to install newly covered wall and headliner panels, and updated granite countertops throughout. New carpet was added to the boat as well, and the interior was left with a bright, fresh look.

Systems (Mechanical/Electrical)

With a power upgrade in the plans, the boatyard mechanical team had their work cut out for them. Before renovations could begin in the engine room, the crew had to remove the old engines and generators to allow for new equipment. Once the engine room was complete, (2) MTU 12V 2000M96 Engines with Twin Disc Controls, (2) Northern Lights 25 kW generators, and a Seakeeper 18 were all installed by the mechanical department. This crew also worked diligently to install a new bow thruster, Seastar Optimus electronic steering, cockpit AC, Fresh Flow heat exchanger, new icemaker, as well as water maker upgrades.

Working together with the mechanical team, the electrical department was ready to get Mama Seata up-to-date with an electrical tune-up. Both the main panel and the bridge panel were upgraded and re-wired. The battery boxes were replaced, and new electronic system controls were installed on the engines. All interior and exterior lighting was upgraded to LED and underwater lights were replaced.

Paint

As soon as the exterior buildout was complete, it was time for the paint department to step in to add some shine. The paint team prepped and painted the engine room and pump room before the mechanical team could install updated power components. The crews sanded, faired, primed, and prepped the boat in its entirety, and Mama Seata then entered the paint booth for top coat. The topside was painted a custom Bayliss white, and a blue and orange boot stripe was added to accentuate her updated color palette.

On the transom, Monique Richter added new transom artwork on top of custom faux teak. After the full paint transformation, faux teak was completed on the half round, toe rail, helm pod, salon door, and jamb courtesy of Izzy Teak.

With a facelift and new power systems, Mama Seata departed Bayliss Boatyard in January of 2023. Currently, you can find her fishing the waters between Costa Rica and Cabo San Lucas. When she’s not in the Pacific, she will fish the Bahamas and Virgin Islands. With a multitude of records already set on this sportfishing yacht, the possibilities for Mama Seata are truly endless.

“Maybe sixteen years from now we will be doing it again. It’s neat to think about,” said Beatty.