We are excited to announce the completion of Wave Paver, our latest 75’ custom sportfishing yacht to hit the water. Now that our work on the project is finished, we look back with pride to just over two years ago when her owners approached us to discuss their second build. It is an honor to build each and every hull, but it is an exceptional privilege when customers choose us for a second time. Wave Paver will be joining a long-standing and very successful fishing program on the tournament circuit, with the original Wave Paver 77’.

Wave Paver 75’ will have the same mission as her 77’ predecessor, just from a different location. As we write this, the 77’ Wave Paver is spending the next couple of seasons off Cape Verde, Africa, and the new 75’ build will likely spend most of her time off the East Coast, Bahamas, and Virgin Islands. Wave Paver wasted no time getting her start in the tournament circuit upon completion. In early June, the Wave Paver team competed at the Big Rock Blue Marlin Tournament on their new vessel in Morehead City, NC. On their first day of fishing, the team won the daily catching four blue marlin. The owner and crew ended the week placing 2nd overall in releases in a fleet of 266 boats.

Since marlin is once again her target species, the new Wave Paver has enhanced capabilities for a variety of conditions. She is equipped with a sophisticated livewell system, a slick set of tuna tubes, along with the typical refinements you would see in a BBW cockpit designed for trolling. In order to support the crew with tackle for every eventuality, we’ve added a well-planned tackle room for rods, Plano boxes, spools of line, dredge bars, etc. This tackle room has the feel of almost another stateroom, with the difference being there are rods on display for quick accessibility.

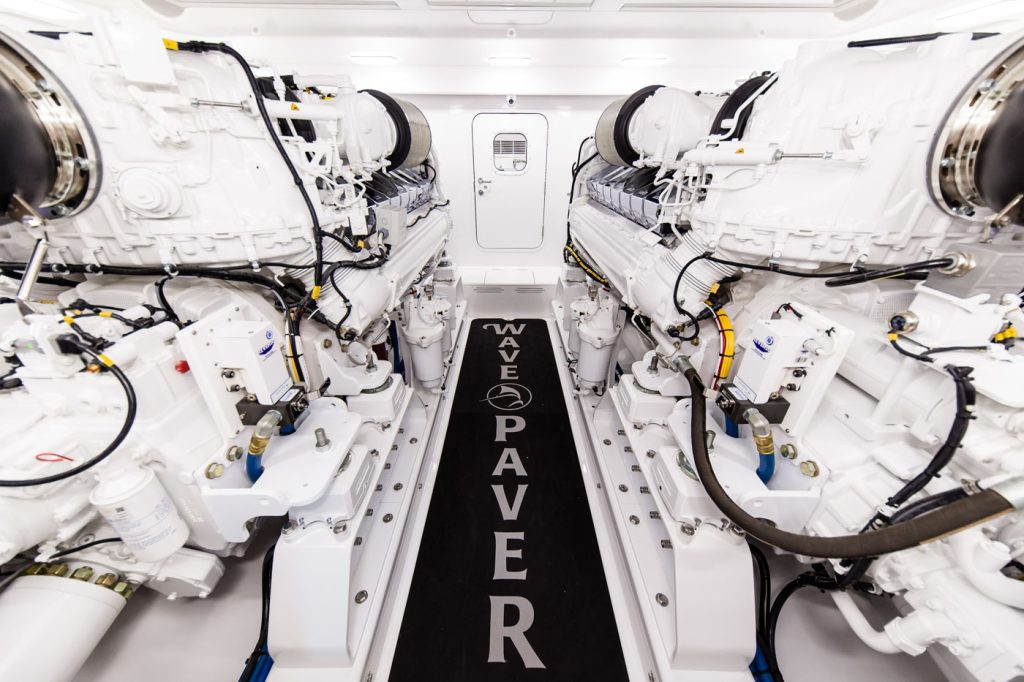

As with most of our builds, Wave Paver will be a traveling boat. Our mission in the build process is to design the systems to be as trouble-free as possible. Thus, one of the primary elements of our recent builds has been the BBW Freshwater Cooling System for all on-board equipment that otherwise would have required raw water cooling. This new system was developed in-house in order to eliminate the troublesome growth, barnacles, and grass that find their way into the important air conditioning and refrigeration systems that are part of every vessel. In fact, even both Seakeepers, the icemaker, and both chillers are freshwater cooled. Our goal is simple; keep maintenance to a minimum, and give the crew more time to concentrate on their targeted species and the things these boats are designed to do.

Wave Paver is the first Bayliss Build to feature a walnut interior. Walnut is a beautiful, yet darker toned wood, but still offers the intricate grain features you will often see in a classic teak boat. Our interior cabinetry team sought and found special dimensional boards to match the tree that we used for the veneers for the entire project. This interior has a very sophisticated and modern look, with crisp edges and tasteful detailing throughout. Our crew utilized hand-picked boards of extra-large dimensions in order to resaw specialty pieces that really helped accentuate the beauty of this species.

Circassian Walnut was also used for accent pieces such as the dinette table and expandable salon coffee table. The combination of the details, the wood species, the granite, and the interior soft goods all combined to make this build one of our most stunning projects to date.

Completely designed in-house, Wave Paver is the result of a 27 month build process with 60,000 man-hours of build time. Bayliss Boatworks is located in Wanchese, NC and employs 110 people in their full-service new construction and boatyard facilities.

SPECIFICATIONS

START DATE: March 2020

DELIVERED: June 2022

LENGTH: 75′ 6″

BEAM: 20’ 10”

POWER: (2) MTU 16V2000 2600hp

GENSET: (2) 38kW Northern Lights

TOP SPEED: 44.6 knots (fully loaded)

FUEL CAPACITY: 2,520 Gallons; Single Tank Aft & Single Tank Forward

WATER CAPACITY: 385 Gallons; Single Integral Tank

INTERIOR LAYOUT: 4 Staterooms, 3 Heads, Day Head, Pantry, Tackle Room

BRIDGE LAYOUT: Bayliss Custom Center Console, Forward Bench Seating, Pocketing Bridge Side Rod Locker Doors, 2 Helm Chairs, 2 Freezers, 1 Drink Box

COCKPIT LAYOUT: Teak deck and coverboards, Transom Fishbox, Rocket Launcher, 3 Mezzanine Freezers, Drink Box, Tackle Storage, Outdoor Grill

SYSTEMS:

– Electrical: (2) 100-amp Hubbell Isolation Transformers Located Port & Starboard

– Seakeepers: SK 18 (Aft) & SK 9 (Forward)

– Exterior Refrigeration: All with Custom Bayliss Stainless Liners. Locations: 3 on bridge, 4 in cockpit. All Run by BBW/Voda Compressors

– Water Makers: (2) Dometic 2,000 Gallon Per Day

– Livewell System: (2) Hooker Pumps, Custom Dedicated Seachests Aft, Tuna Tubes

– Rupp Hydraulic Outriggers

– Tower: Palm Beach Towers

– Bayliss Boatworks Designed Freshwater Cooling System

Serving the Following Components:

– (2) Dometic Chillers

– Dometic 1000 lb. Per Day Icemaker

– (3) Custom Voda Refrigeration Units

– (2) Seakeepers